- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

LED On/Off Detection

08-17-2021 03:50 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Hi all,

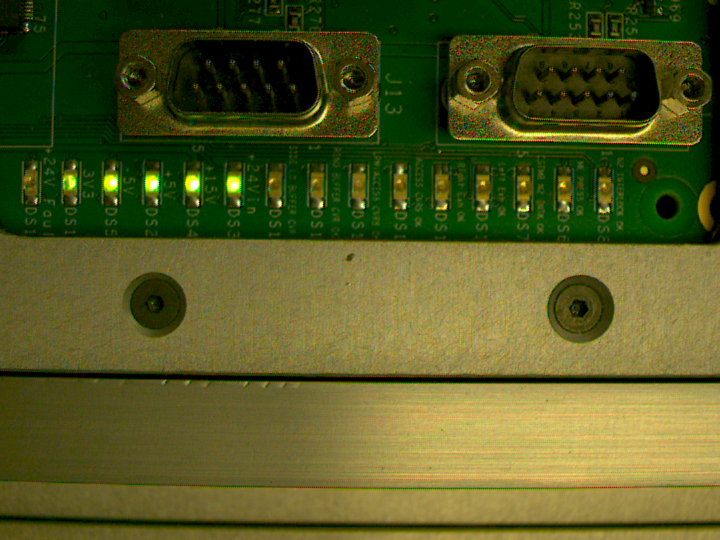

I have this image that I pulled via my Basler camera and NI Vision Assistant. I'm trying to detect if each of the LEDs are on/off, the first thing I've done is extracted the green layer. The two tools I've been using is Line Profile and Histogram where line profile cuts across the LED and Histogram I've put a box over the entire LED. Line Profile looks extremely simple and I may go ahead with that as my option.

The camera and UUT may move, so before this step I've added a Find Straight Edge which captured my edge. Then when using either tool the "Reposition Region of Interest" is greyed out and I can't figure out how to use a relative coordinate system against the edge.

My 'vision' experience comes from Keyence's vision tools so creating evaluations was a breeze and I'm trying to figure out how to do that with NI Vision Assistant with CVI. I still don't know how this is going to convert into C code nor do I know how to get 'results' of each step of the script or how this tools is to be used really...

Below is the unedited image and attached is the script I've worked on.

Thanks in advance.

08-18-2021 10:30 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Went through this https://www.ni.com/pdf/manuals/372228p.pdf

Now I figured out how to set a coordinate system and generate code. However, still confused how I can get access to the line profile tool. If it was a 2D int array I'd be set. Just don't know what to do here....

08-18-2021 11:12 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

After running the code and looking at each call to IVA_LineProfile_Gray I see my tools being called. Each labelled as roi0-6. Is common practice to use Vision Assistant to generate everything, rename roi0-6 with the respective 'tool name' and make it global so you can access it and make judgements after the full script is run?

Is there anyway for Vision assistant to push the Step Name into roi0-6 so I don't have to manually edit it? Not an issue once all ROI's are stable, but feels like it will be annoying if I have to move/edit the script order.

08-27-2021 11:12 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

I saw you hadn't had any replies so I thought I'd try to help.

I couldn't open your Vision Assistant file. I get an "invalid script file selected" error, which may be because I'm on 2015 and you're likely using a newer version.

However, I'm puzzled by the approach you're taking. If you just want to know if each LED is on or off couldn't you do that with thresholding and particle analysis?

A couple of other comments if I may.

I never use a color camera unless I absolutely have to. It gives you an 8 bit image and saves having to separate out a color plane.

It looks as though you're using a short focal length lens and a short working distance, which is distorting where the LEDs appear. Could you go with a longer lens and working distance? And why not aim the camera at the LEDs if that's all you want to see?

Last, Vision Assistant is very much just a prototyping tool. I use it for playing around with ideas and experimenting. When I think I have something that's going to work I use the Create LabVIEW VI function and then cut-n-paste the parts I want into a new vi.

Hopefully this is of some help. Get back to me with any other questions so I can fail to answer them too.

02-07-2022 01:13 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

Fully agreed the proposal of thresholding and particle analysis in LabVIEW rather than VA.

if I may add more about the coordination system. The normal process is as following:

In a template:

1) Search a pattern in image which as an "Anchor".

2) Setup the base coordination system based on information(origin, X, Y) extracted from the "anchor".

2) Define the ROI(in your case may be an rectangle to include all LEDs) in base coordination system.

For image to inspect:

1) Search the location of pattern save to "Anchor".

2) Update the coordination system based on the new location of "Anchor".

3) Place the ROI in new coordination system(the ROI position relative to Anchor are same)

4) Perform thresholding and particle analysis to detect LED on/off.

Gaoke

09-23-2022 08:12 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

选择C代码,在工具中生成代码即可

09-29-2022 09:36 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report to a Moderator

There are so many fun ways to make this measurement.

Per other comments, color cameras are never a good idea unless you actually need to extract color data. Even if the LED change color, it might well be possible to differentiate color differences by using a color filter and sorting by intensity.

Color cameras almost all use Bayer Filters to decode color information at the cost of resolution. In this case resolution does not seem to be a problem.

No Matter, if you have a color camera it will work just fine.

If the part is fixtured so that the LEDs are in the same place in the image, things get a lot easier, but there is a fiducial mark on the board that can be used as a reference as well.

I hope you have already solved the problem. Keep the thread alive until you do and let us know the final result.